Application field:It is widely used in the processing of precision parts in automobile, aerospace, food and chemical machinery, mould, high-speed railway, electronics and other industries etc.

- Rapid feed rate (X/Z axis):30/36 m/min

- Travel (X/Z axis):190/540mm

- The two axis guide rail is carried by roller wire rail, with high rigidity, low friction and low noise.

- C3 screw rod is of pr-tension structure to eliminate some thermal extension. The screw rod shaft adopts self-lubricating to prolong the service life of the bearing.

- Large foundation parts are made of high-quality resin sand molding and high-strength casting materials, so that the machine tool has high rigidity and stability.

规格参数表

| Item | Unit | CLS-560 |

| Travel | ||

| X axis travel | mm | 190 |

| Z axis travel | mm | 540 |

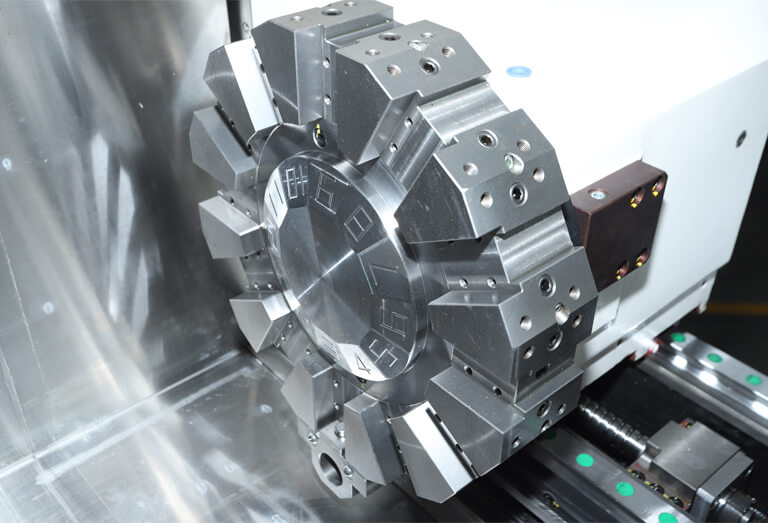

| Turret | ||

| Number of installed tools | ea | 12 |

| Maximum diameter tool size | mm | 20x20 |

| Maximum boring tool diameter | mm | Φ32 |

| Tailstock | ||

| Tailstock stroke | mm | 450 |

| Tailstock taper hole | MT4(External movable center) | |

| Processing capacity | ||

| Maximum cyclotron diameter | mm | Φ560 |

| Maximum machining diameter | mm | Φ330 |

| Maximum turning length | mm | 500 |

| Spindle through hole diameter | mm | Φ66 |

| Maximum bar machining diameter | mm | Ø51 |

| Spindle power | ||

| Spindle Motor(Continuous 30 minutes) | kW | 11/15 |

| Spindle Maximum speed | mm | 4500 |

| Spindle form | KSA | A2-6 |

| Chuck size | inch | 8"Hollow standard configuration |

| Spindle runout(root) | mm | 0.005 |

| Spindle runout(300mm) | mm | 0.008 |

| Accuracy | ||

| Positioning accuracy(X/Z) (Full travel) | mm | 0.010/0.015 |

| Repeat positioning accuracy (X/Z)(Full travel) | mm | 0.006 |

| Feed rate | ||

| Rapid feed rate(X/Z) | mm/min | 30/36 |

| System | ||

| Controller | FANUC 0i-TF | |

| Oil pressure system | ||

| Water tank capacity | liter | 150 (Front Drain) |

| Power | ||

| Power demand | kVA | 20 |

| Other | ||

| Floor area(Length*Width) | mm | 3900x1625 |

| Machine height(Maximum) | mm | 1640 |

| Machine weight | T | 3.5 |

Create greater value for you and enhance product competitiveness

Contact Us