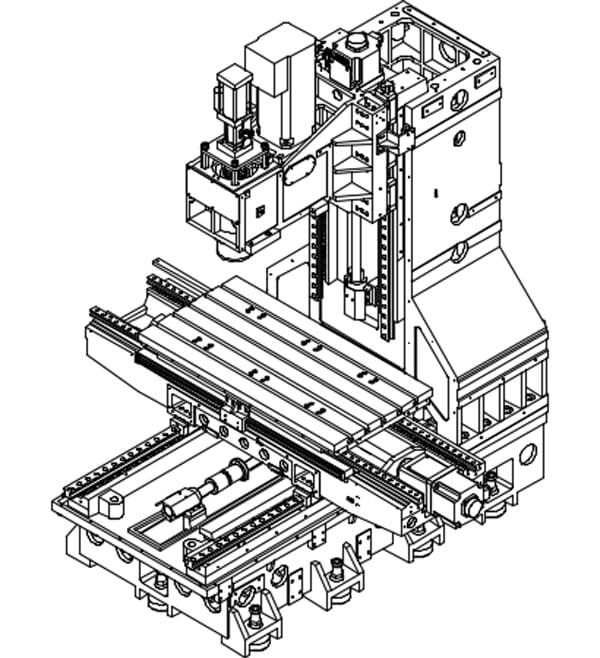

Application field:It is widely used in communication electronics, automobile and locomotive parts production and automatic parts processing.

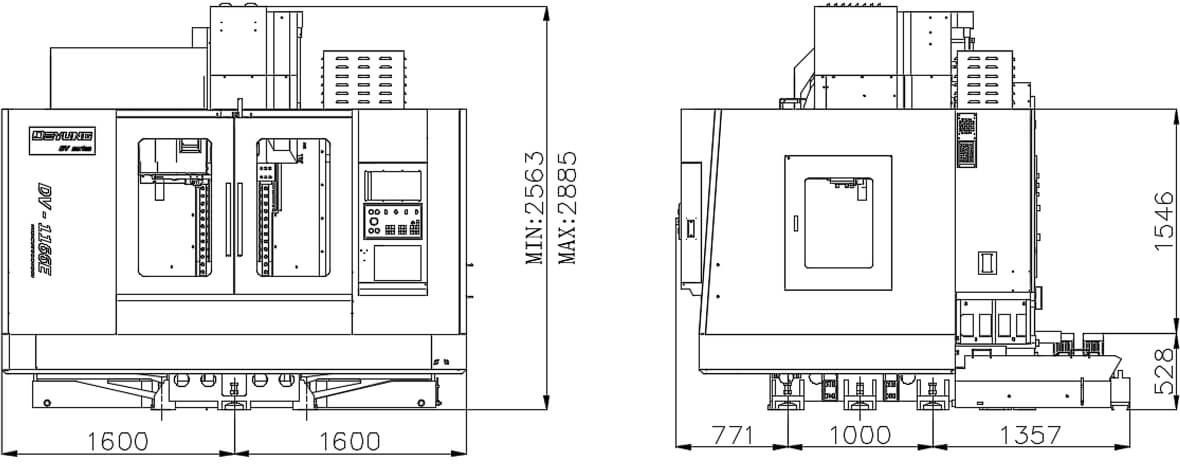

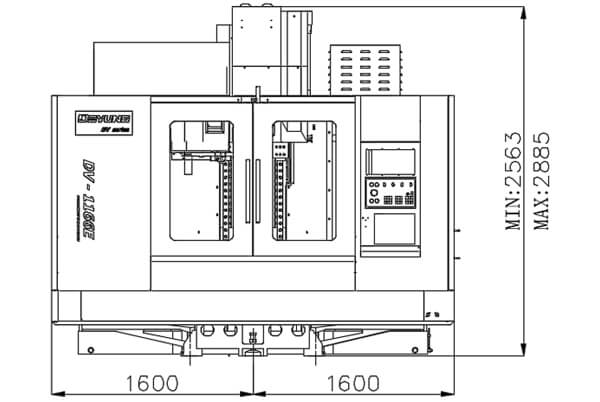

- DV-1166

- Rapid feed rate (X / Y / Z axis):36/36/36m/min

- Three axis travel (X / Y / Z axis):1100/620/600mm

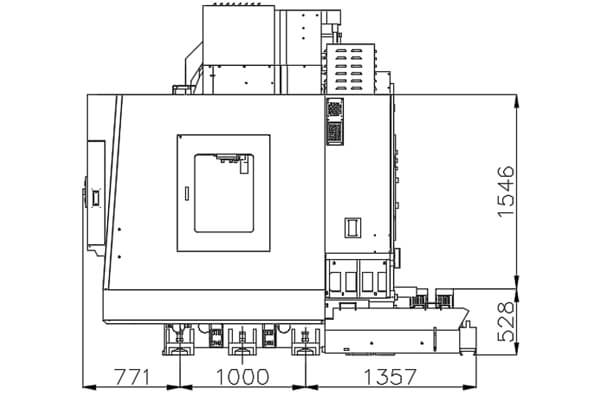

- DV-1266

- Rapid feed rate (X / Y / Z axis):36/36/36m/min

- Three axis travel (X / Y / Z axis):1200/620/600mm

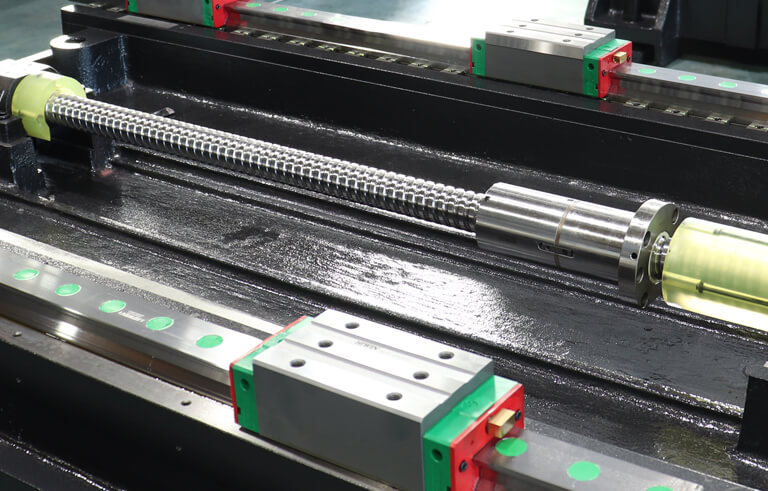

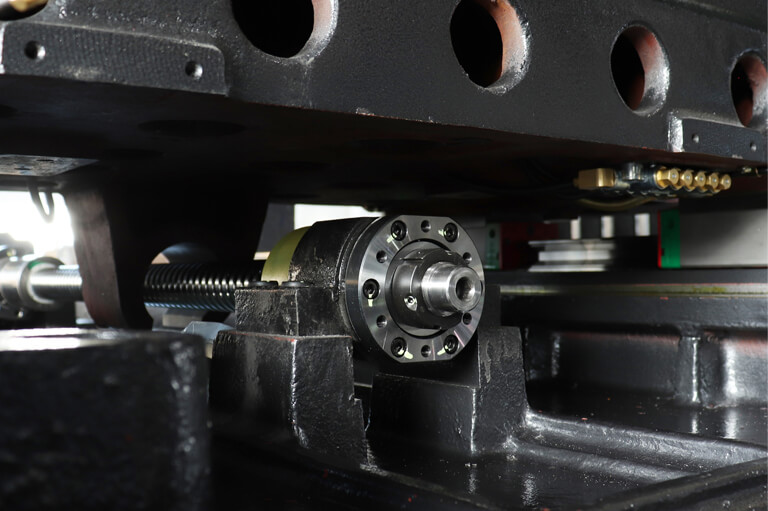

- Screw pre tension design: C3 grade ∅ 40xp12mm screw is adopted for the trivial, and the assembly process of pre tension at both ends is adopted to strengthen the axial rigidity and reduce the thermal extension of the screw.

- High rigid bed structure. Through FEM finite element structural analysis, a large number of stiffeners are used inside the casting to optimize the internal stress structure of the whole machine and ensure the rigidity and thermal variation stability of the whole machine.

- The three-axis roller rail has small friction resistance, shortens the fast displacement time and improves the production efficiency; At the same time, through excellent assembly process, high-precision product processing can be completed.

- The large span base structure and two 45mm roller rails are adopted to provide the machine with very strong bearing capacity and meet the high rigidity requirements during heavy cutting.

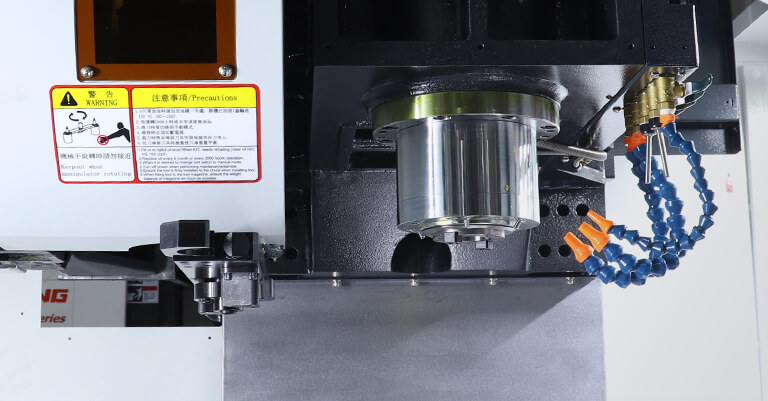

- The front spindle is equipped with annular water spray to effectively cool the cutting tools. At the same time, the internal air curtain negative pressure design extends the service life and ensures the reliable use of the spindle for long-term high-speed operation.

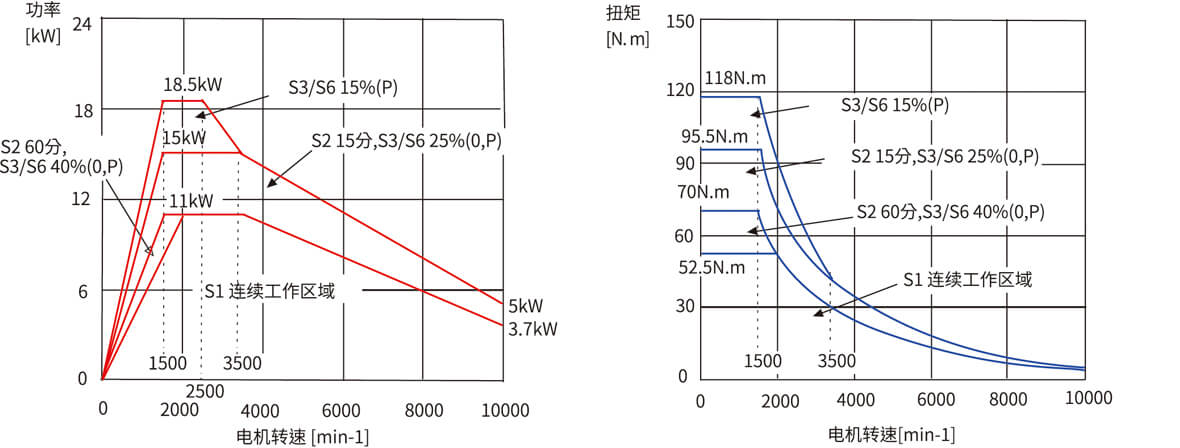

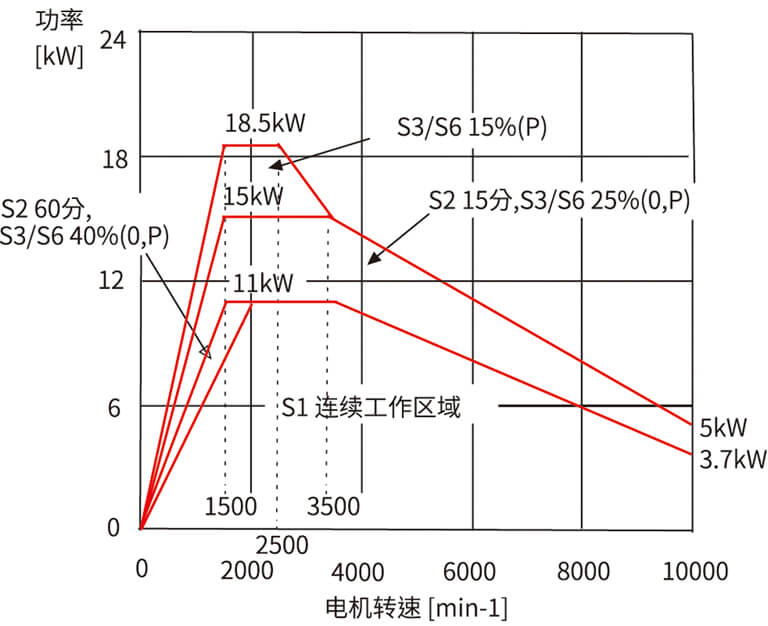

皮带式主轴扭矩

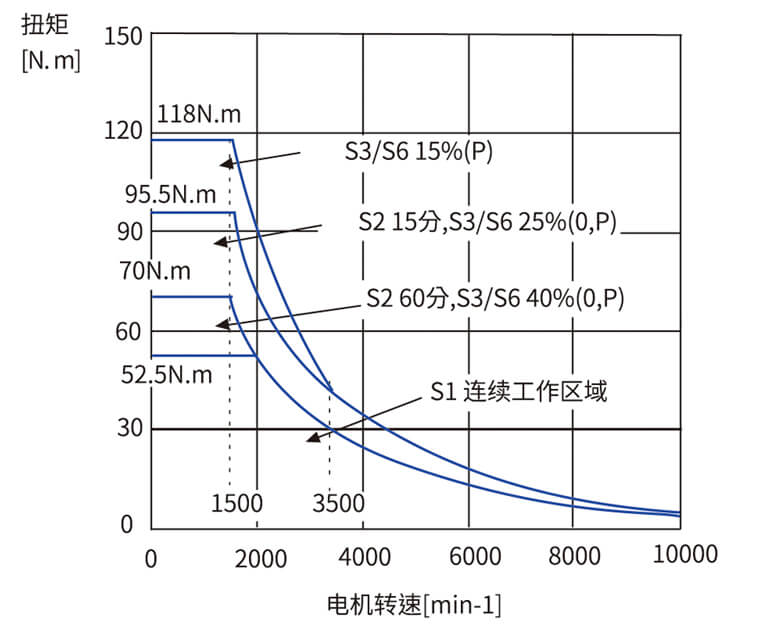

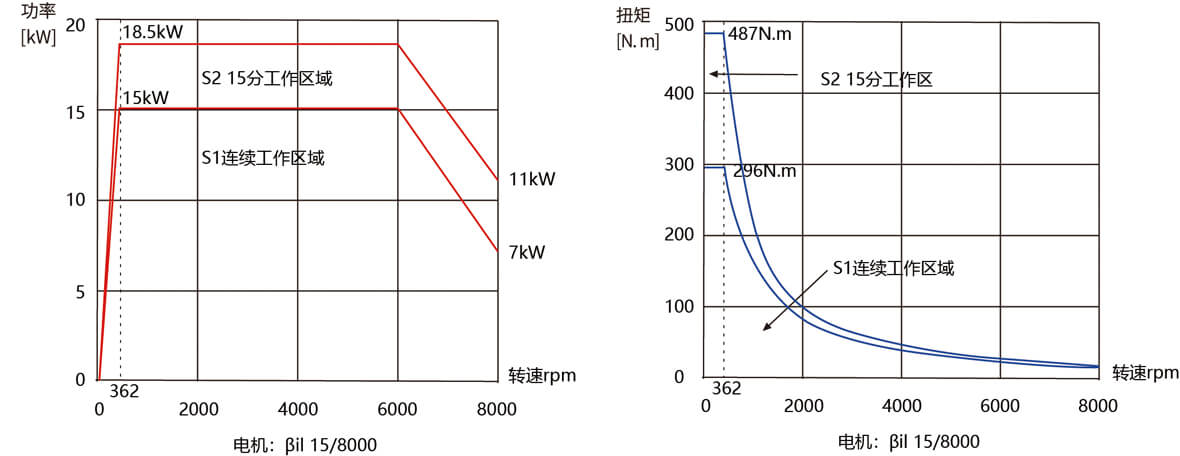

齿轮式主轴扭矩

规格参数表

| Item | Unit | DV-1166 | DV-1266 |

| Travel | |||

| X-axis travel | mm | 1100 | 1200 |

| Y-axis travel | mm | 620 | 620 |

| Z-axis travel | mm | 600 | 600 |

| Distance nose to table | mm | 125-725 | 125-725 |

| Table | |||

| Table size (X*Y) | mm | 1200x600 | 1300x600 |

| Table Load | kg | 900 | 1000 |

| T slot (size * distance *number) | mm | 18x5x100 | 18x5x100 |

| Spindle | |||

| Spindle Speed | rpm | 10-10000 | 10-10000 |

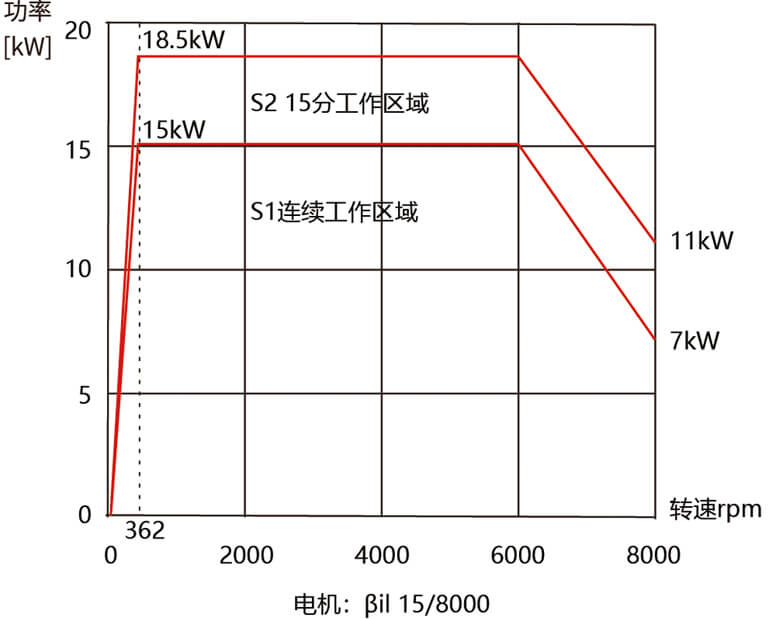

| Spindle motor | kW | 11/15 | 11/15 |

| Spindle taper | BT40 | BT40 | |

| Spindle rate | |||

| Rapid feed rate (X/Y/Z) | m/min | 36/36/36 | 36/36/36 |

| Cutting feed rate | mm/min | 1-10000 | 1-10000 |

| Tool change system (Optional) | |||

| Tool storage capacity (Standard/Optional) | set | 24/30 | 24/30 |

| Tool library form | Knife arm type | Knife arm type | |

| Max.tool dia. ( full / adjacent) | mm | φ80/φ150 | φ80/φ150 |

| Max. Tool length | mm | 300 | 300 |

| Max. Tool weight | kg | 8 | 8 |

| Accuracy | |||

| Positioning accuracy (Full travel) | mm | 0.012 | 0.012 |

| Repeat positioning accuracy (Full travel) | mm | 0.006 | 0.006 |

| Other | |||

| Controller | FANUC 0I-MF | FANUC 0I-MF | |

| Air pressure demand | kg/cm2 | 6 | 6 |

| Electricity demand | kVA | 25 | 25 |

| Gross weight | T | 6.5 | 6.6 |

| Area occupied (Length * Width) | mm | 2780*3150 (Back Drain) | 3420*3150 (Back Drain) |

Create greater value for you and enhance product competitiveness

Contact Us