It is widely used in mass production of automobile and locomotive parts, medical equipment, aviation and communication electronics, and all kinds of precision mold processing and production.

- Rapid feed rate (X / Y / Z axis):36/36/36m/min

- Three axis travel (X / Y / Z axis):1020/520/550mm

- The integrated design of bearing seats and saddles on both sides, combined with precision machining and high-quality assembly technology, ensures smooth parallelism.

- The three-way chip removal design at the bottom, combined with the combination of high inclined plate and high flow pump, makes the chip removal reliability of the base excellent.

- Humanized operation design, convenient knife loading, convenient cleaning, good accessibility, embedded pedal space, high-efficiency LED work light, making the operation space spacious and bright, and the whole machine conforms to ergonomic design.

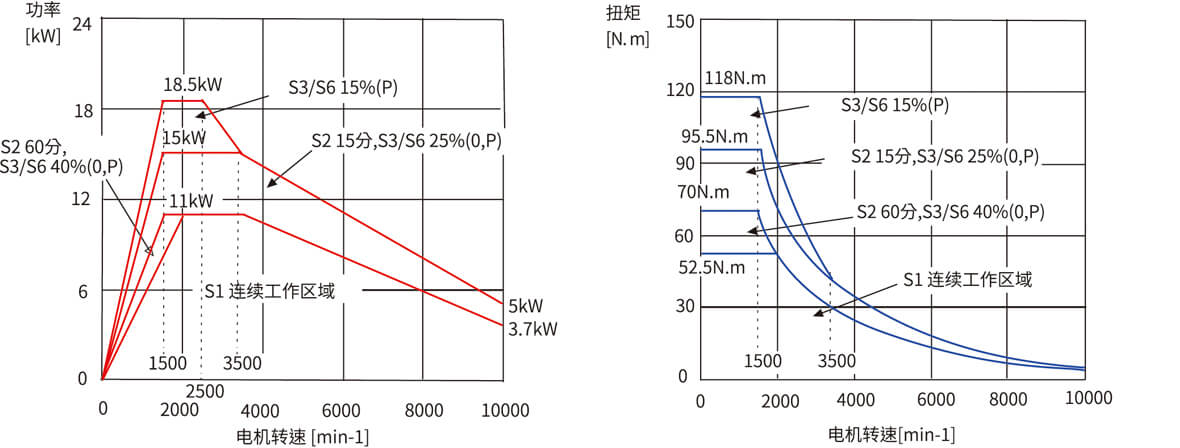

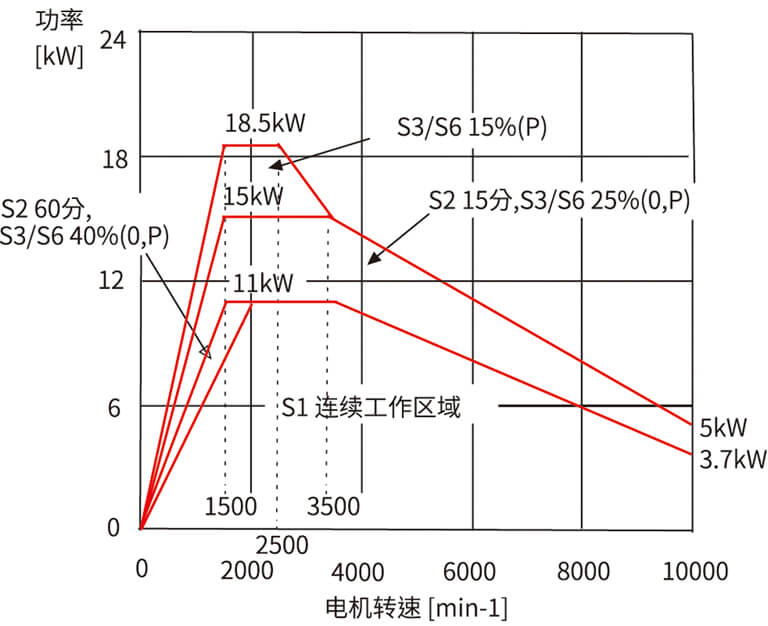

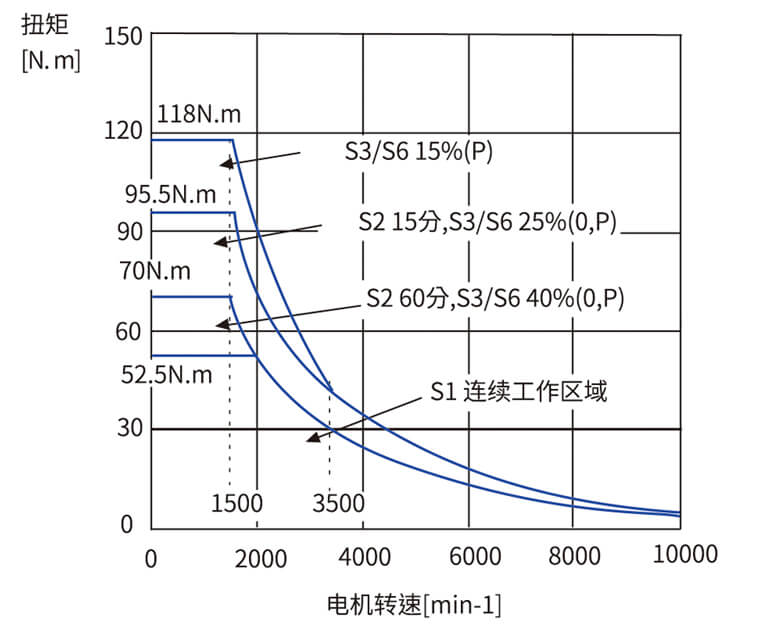

皮带式主轴扭矩

规格参数表

| Item | Unit | CV-1055F |

| Travel | ||

| X-axis travel | mm | 1020 |

| Y-axis travel | mm | 520 |

| Z-axis travel | mm | 550 |

| Distance nose to table | mm | 145-695 |

| Table | ||

| Table size (X*Y) | mm | 1120x520 |

| Table Load | kg | 600 |

| T slot (size * distance *number) | mm | 18x5x100 |

| Spindle | ||

| Spindle Speed | rpm | 10-8000 |

| Spindle motor | kW | 11/15 |

| Spindle taper | BT40 | |

| Spindle rate | ||

| Rapid feed rate (X/Y/Z) | m/min | 36/36/36 |

| Cutting feed rate | mm/min | 1-10000 |

| Tool change system (Optional) | ||

| Tool storage capacity (Standard/Optional) | set | 24/30 |

| Tool library form | Knife arm type | |

| Max.tool dia. ( full / adjacent) | mm | φ80/φ150 |

| Max. Tool length | mm | 300 |

| Max. Tool weight | kg | 8 |

| Accuracy | ||

| Positioning accuracy (Full travel) | mm | 0.010 |

| Repeat positioning accuracy (Full travel) | mm | 0.005 |

| Other | ||

| Controller | FANUC 0I-MF | |

| Air pressure demand | kg/cm2 | 6 |

| Electricity demand | kVA | 25 |

| Gross weight | T | 6 |

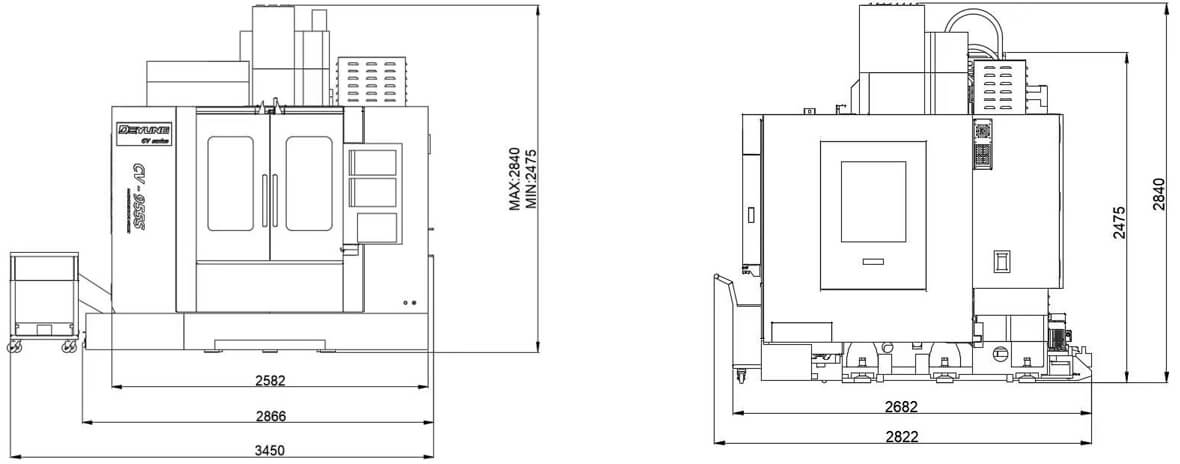

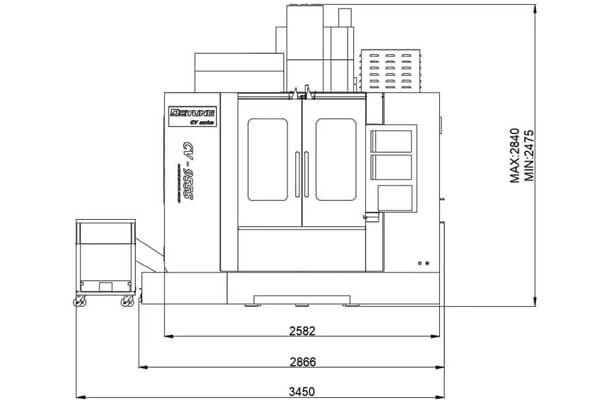

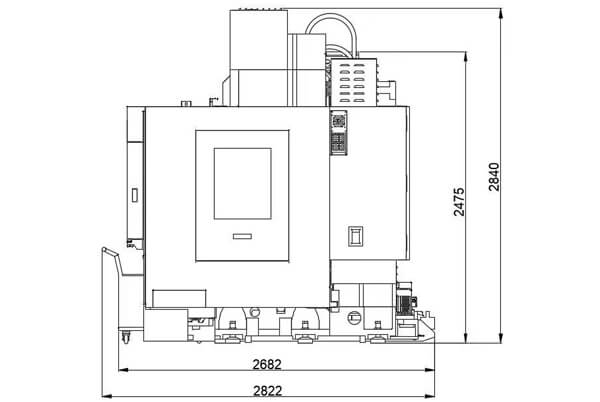

| Area occupied (Length * Width) | mm | 2690x2900 (Back Drain) |

Create greater value for you and enhance product competitiveness

Contact Us