Application field: It is suitable for mass production of automobile parts, medical equipment, aviation and communication electronics precision mold processing and production.

- Rapid feed rate(X / Y / Z axis):20/20/20m/min

- Three axis travel(X / Y / Z axis):1800/900/800mm

- The short nose spindle design has better strength and rigidity. The spindle can be equipped with annular water spray function to effectively prolong the tool life.

- The three-axis motor and screw adopt direct transmission design, without noise, clearance and vibration caused by belt or gear drive. The rapid displacement of the three-axis can reach 48m / min, which can greatly save non processing time.

- It is directly driven by an enlarged motor and its own brake servo motor, which is stable and reliable when performing high-speed milling or drilling.

规格参数表

| Item | Unit | CV-1890 |

| Travel | ||

| X-axis travel | mm | 1800 |

| Y-axis travel | mm | 900 |

| Z-axis travel | mm | 800 |

| Distance nose to table | mm | 200-1000 |

| Table | ||

| Table size (X*Y) | mm | 2000x900 |

| Table Load | kg | 2500 |

| T slot (size * distance *number) | mm | 22x5x160 |

| Spindle | ||

| Spindle Speed | rpm | 10-6000 |

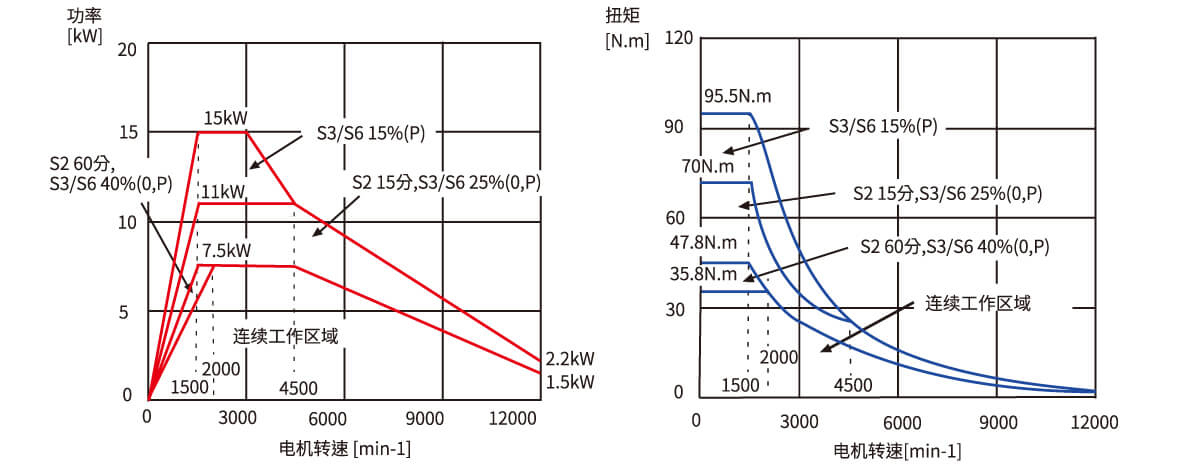

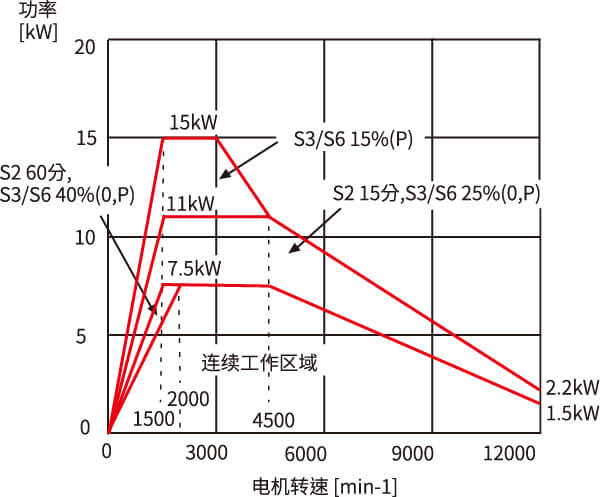

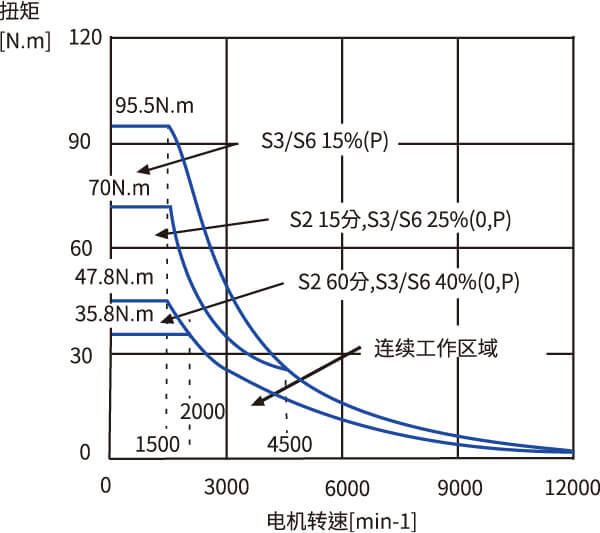

| Spindle motor | kW | 15/18.5 |

| Spindle taper | BT50 | |

| Spindle rate | ||

| Rapid feed rate (X/Y/Z) | m/min | 20/20/20 |

| Cutting feed rate | mm/min | 1-10000 |

| Tool change system (Optional) | ||

| Tool storage capacity (Standard/Optional) | set | 24/30 |

| Tool library form | Knife arm type | |

| Max.tool dia. ( full / adjacent) | mm | φ110/φ200 |

| Max. Tool length | mm | 350 |

| Max. Tool weight | kg | 15 |

| Accuracy | ||

| Positioning accuracy (Full travel) | mm | 0.020 |

| Repeat positioning accuracy (Full travel) | mm | 0.010 |

| Other | ||

| Controller | FANUC 0I-MF | |

| Air pressure demand | kg/cm2 | 6 |

| Electricity demand | kVA | 50 |

| Gross weight | T | 16 |

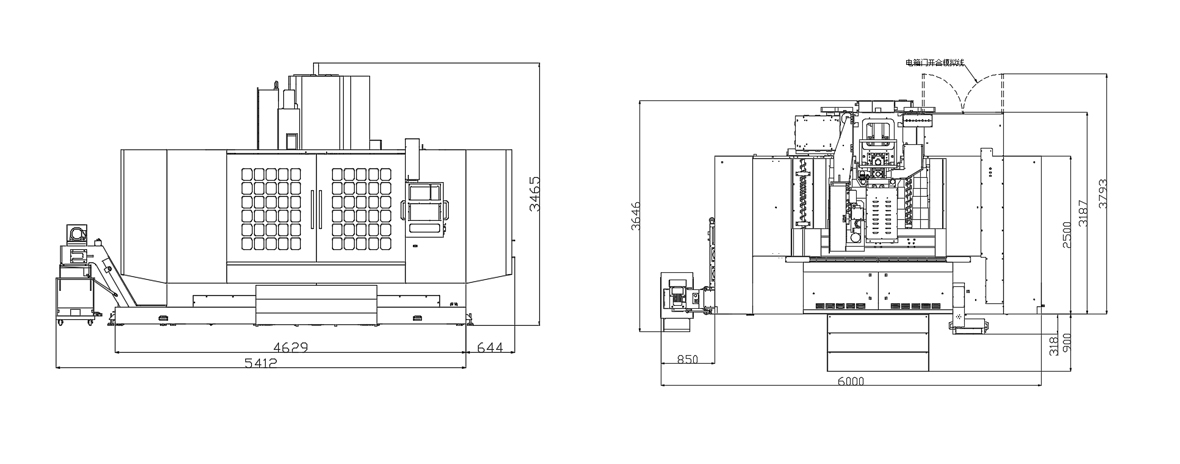

| Area occupied (Length * Width) | mm | 6000x5150 (Front Drain) |

Create greater value for you and enhance product competitiveness

Contact Us