Application field:It is widely used in communication industry, precision machining and aluminum alloy processing.

- Rapid feed rate ( X/Y/Z/Waxis ):

- HBD-4026-130D:8/8/8/6m/min

- HBD-3018-130:8/8/8/6m/min

- HBD-3020-110:8/8/8/6m/min

- HBD-3026-130:8/8/8/6m/min

- Three axis travel ( X/Y/Z axis ):

- HBD-4026-130D:4000/2600/2000mm

- HBD-3018-130:3000/1800/1500mm

- HBD-3020-110:3000/2000/1500mm

- HBD-3026-130:3000x2600x1500mm

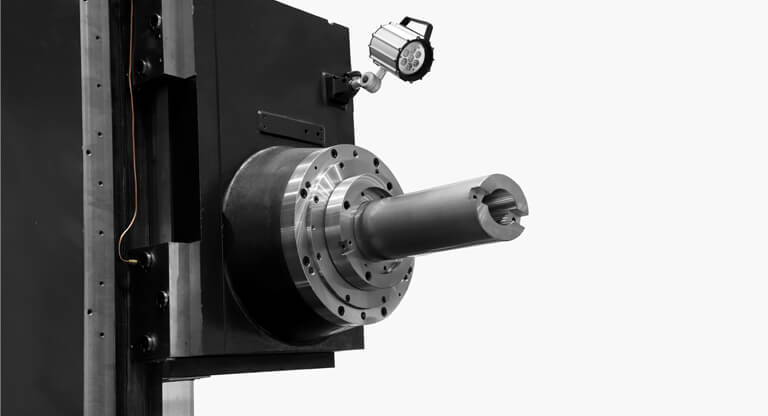

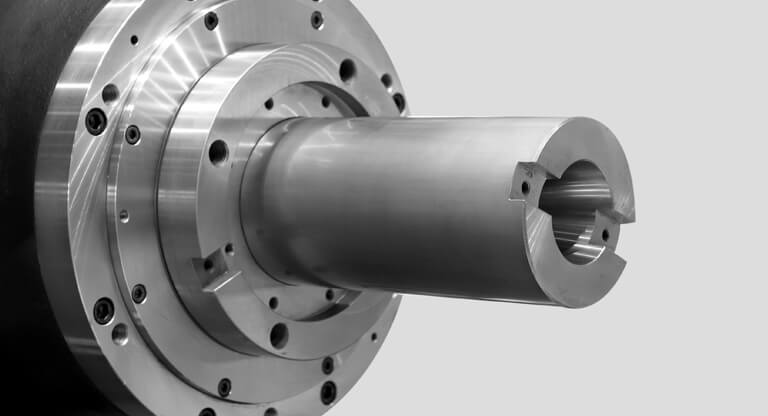

- Each Deyang spindle is manufactured under strict quality control. Under the double insurance of reconfirmation after inspection, the assembly of each spindle, from parts to semi-finished products, is subject to dynamic balance correction and inspection. The spindle will not be installed on the machine until it is confirmed that all accuracy reaches the standard value.

- The main shaft design of double-layer shaft sleeve makes the main shaft stably supported during processing. When the extension sleeve is applied, it rotates simultaneously with minimal wear.

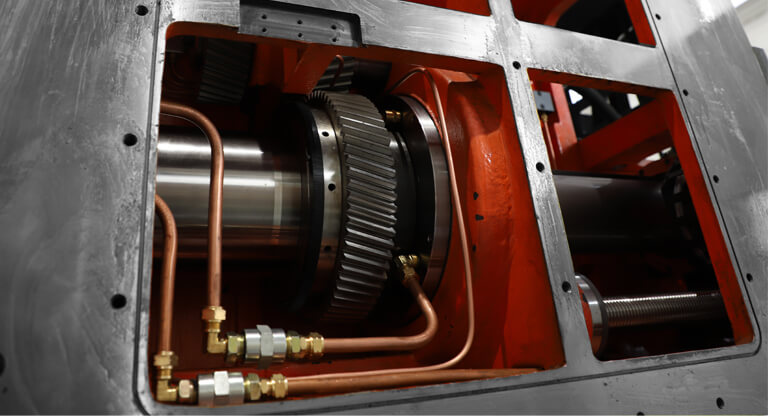

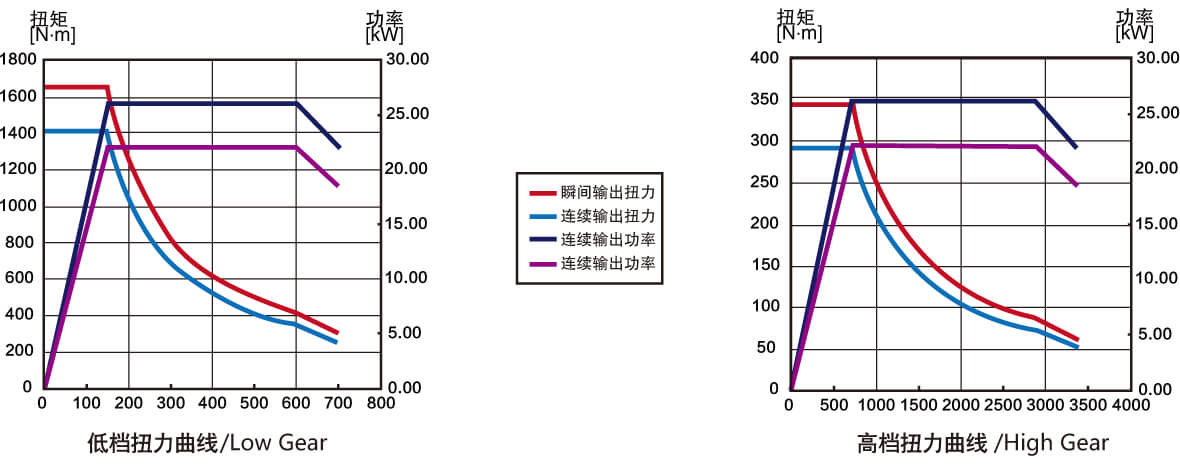

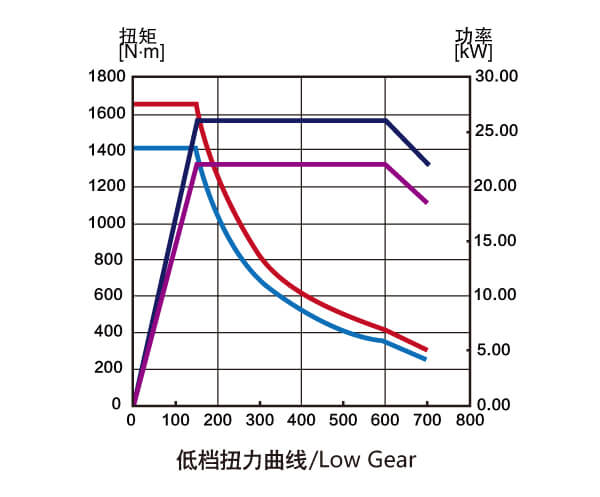

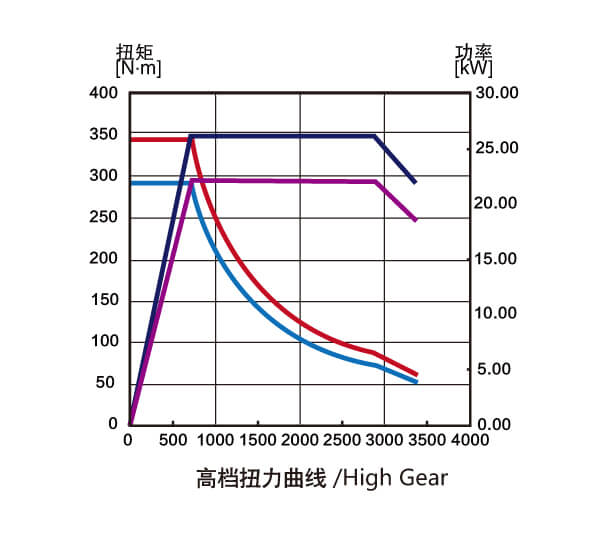

- Helical gear transmission, high torque spindle, full shower circulating oil cooling design, stable speed, providing the most important cutting capacity of boring machine function.

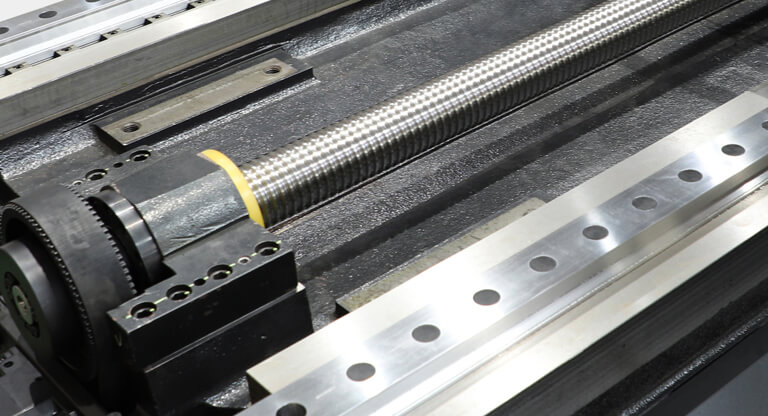

- The axial movement has a fully supported structural design, combined with precise ball screw transmission to obtain excellent displacement accuracy. The internal pipeline circuit layout focuses on safety, cleanliness and beauty.

- The boring bar shaft is supported by large-diameter bearings, which can highlight its excellent machining stability during cutting.

- The structure of large-diameter preloaded ball screw combined with axial heavy-duty roller guide rail forms the perfect structure of high rigidity machine tool.

- The independent lateral movement of the column and the uniaxial movement of the worktable allow the processing of heavy workpieces and improve the accessibility of workpieces.

- The three-axis is driven by high-precision (C3 level) large-diameter ball screw, and the whole series is driven by AC servo motor, with high precision and good rigidity.

规格参数表

| Item | Unit | HBD-4026-130D | HBD-3018-130 | HBD-3020-110 | HBD-3026-130 |

| Travel | |||||

| X axis travel | mm | 4000 | 3000 | 3000 | 3000 |

| Y axis travel | mm | 2600 | 1800 | 2000 | 2600 |

| Z axis travel | mm | 2000 | 1500 | 1500 | 1500 |

| W axis travel | mm | 700 | 700 | 700 | 700 |

| Distance for spindle nose to work table | mm | -50-2550 | 200-2000 | 35-2035 | 0-2600 |

| Distance for spindle nose to work table center | mm | 0-2700 | -180-2020 | 160-2160 | -40-2160 |

| Worktable- | |||||

| Table area(X*Y) | mm | 1800x2200 | 1200x1400 | 1400x1600 | 1600x1800 |

| Max. table load | kg | 2000 | 5000 | 8000 | 15000 |

| Axis B indexing | mm | 0.001 | 0.001 | 0.001 | 0.001 |

| T slot (size * distance *number) | mm | 24x7x200 | 22x5x200 | 24x7x200 | 24x7x200 |

| Spindle | |||||

| Spindle Speed | rpm | 40-2500 | 40-2500 | 40-2500 | 40-2500 |

| Spindle motor(continuous / 30 minutes) | kW | 22/26 | 22/26 | 22/26 | 22/26 |

| Spindle bore specifications | BT50 | BT50 | BT50 | BT50 | |

| Tool change system | |||||

| Tool library form | ISO | MAS403-BT50 | MAS403-BT50 | MAS403-BT50 | MAS403-BT50 |

| Tool storage capacity | 40(60,90) | 40(60,90) | 40(60,90) | 40(60,90) | |

| Tool change time | sec | 90 | 90 | 90 | 90 |

| Max.tool dia. ( full / adjacent) | mm | Ø125/Ø245 | Ø125/Ø245 | Ø125/Ø245 | Ø125/Ø245 |

| Max. Tool length | mm | 400 | 400 | 400 | 400 |

| Max. Tool weight | kg | 25 | 25 | 25 | 25 |

| Spindle rate | |||||

| Rapid feed rate(X/Y/Z/B) | m/min | 8/8/8/6rpm | 8/8/8/6/2rpm | 8/8/8/6/2rpm | 8/8/8/6/2rpm |

| Cutting feed rate | mm/min | 1-6000 | 1-5000 | 1-5000 | 1-5000 |

| Motor | |||||

| Electricity demand | kVA | 75 | 70 | 70 | 70 |

| Cooler bin | |||||

| Water tank capacity | L | 450 | 300 | 300 | 300 |

| Oil tank capacity | L | 6 | 6 | 6 | 6 |

| Accuracy | |||||

| XYZ axis positioning accuracy(VDI/DGQ3441) | mm | 0.025(Full travel) | X0.025/Y0.02/Z0.02 | X0.025/Y0.02/Z0.02 | X0.025/Y0.025/Z0.02 |

| XYZ axis repeat positioning accuracy(VDI/DGQ3441) | mm | 0.02 | X0.02/Y0.015/Z0.015 | X0.02/Y0.015/Z0.015 | X0.02/Y0.02/Z0.015 |

| Other | |||||

| Machine weight | kg | 45000 | 32000 | 32000 | 36000 |

| Machine height | mm | 5200 | 4400 | 4600 | 5200 |

| Area occupied | mm² | 10500x7500 | 7500x6500 | 7500x7500 | 7500x7800 |

Create greater value for you and enhance product competitiveness

Contact Us